Quality Assurance

Esteem is dedicated to providing our customers with product that meets or exceeds their expectations. This is accomplished by involving the quality department in each step in the manufacturing process, nurturing a culture of continuous improvement, maintaining a dedicated, quality minded workforce and utilizing state of the art measurement equipment.

ISO 9001:2015 Certified and ITAR Registered

Nikon CNC Video Measuring System:

- NEXIV VMZ-R4540

- Accuracy to < 2 microns (.000080”)

Keyence Instant Measurement IM-6225

Keyence Portable CMM XM-1600

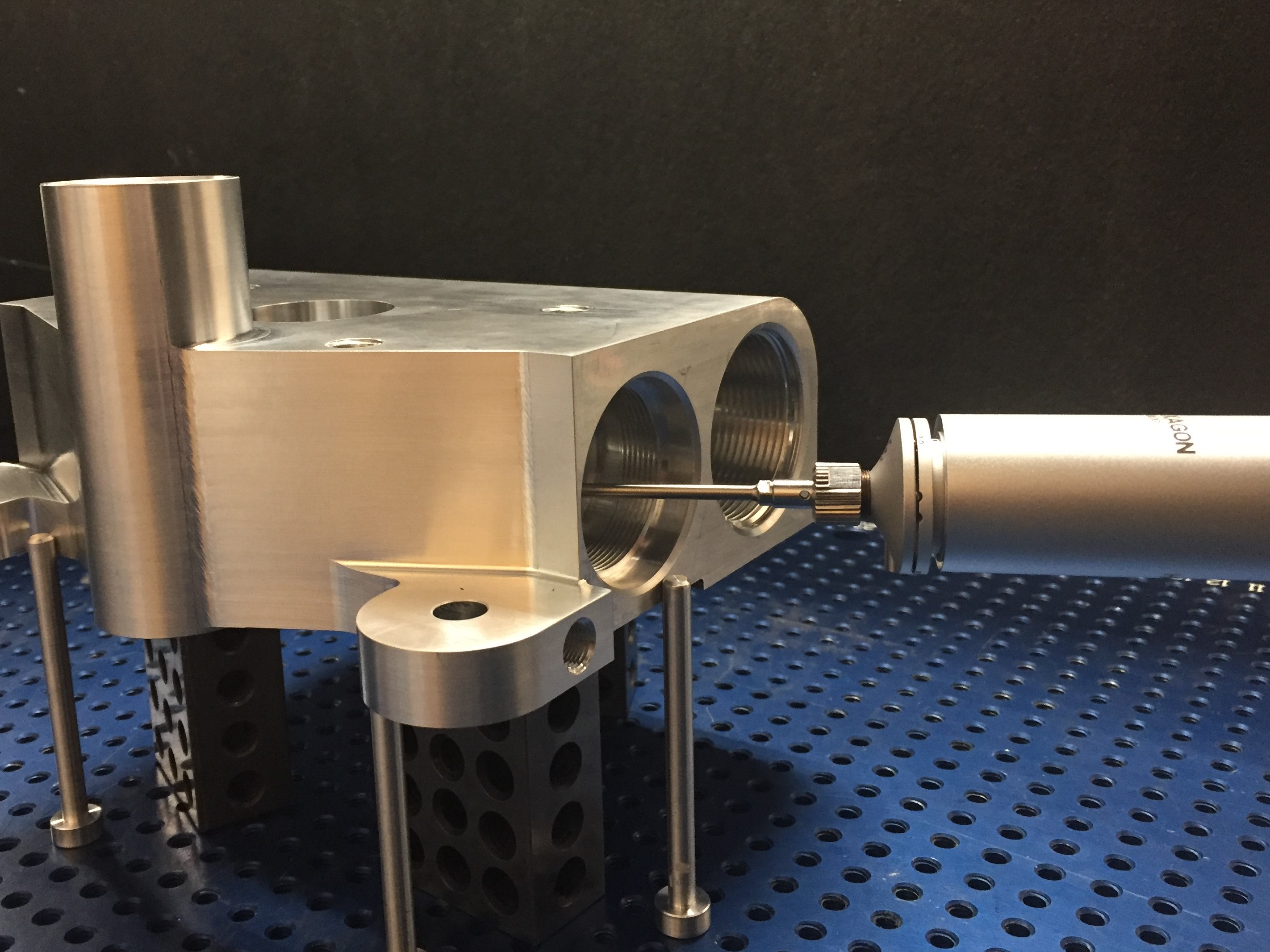

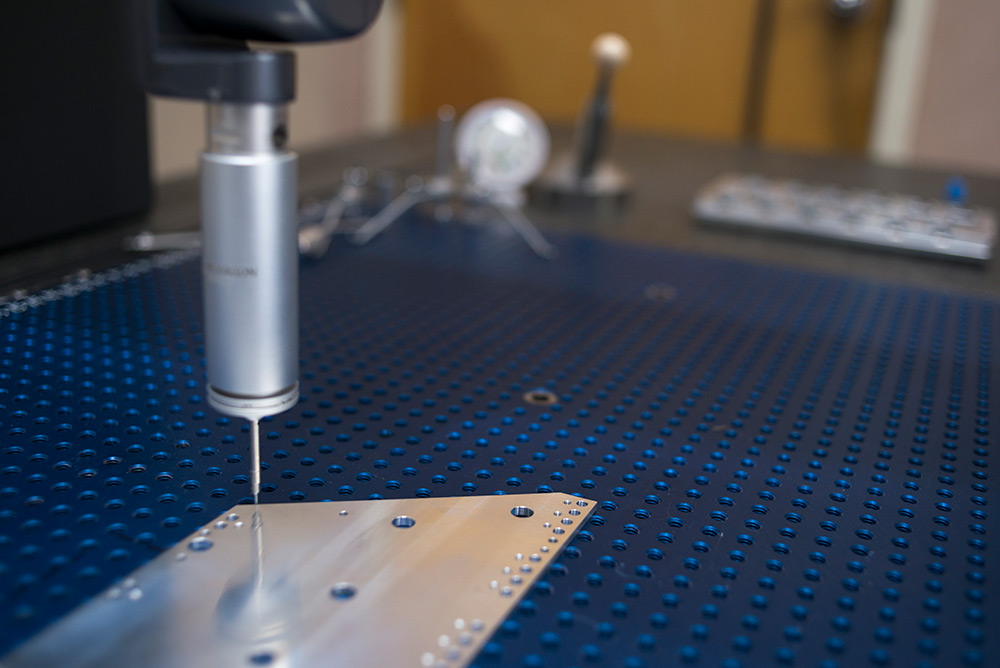

Brown & Sharpe Xcel DCC CMM:

- 650mm (25.6”) x 1000mm (39.4”) x 650mm (25.6”)

- PC-DMIS cad software and probe scanning

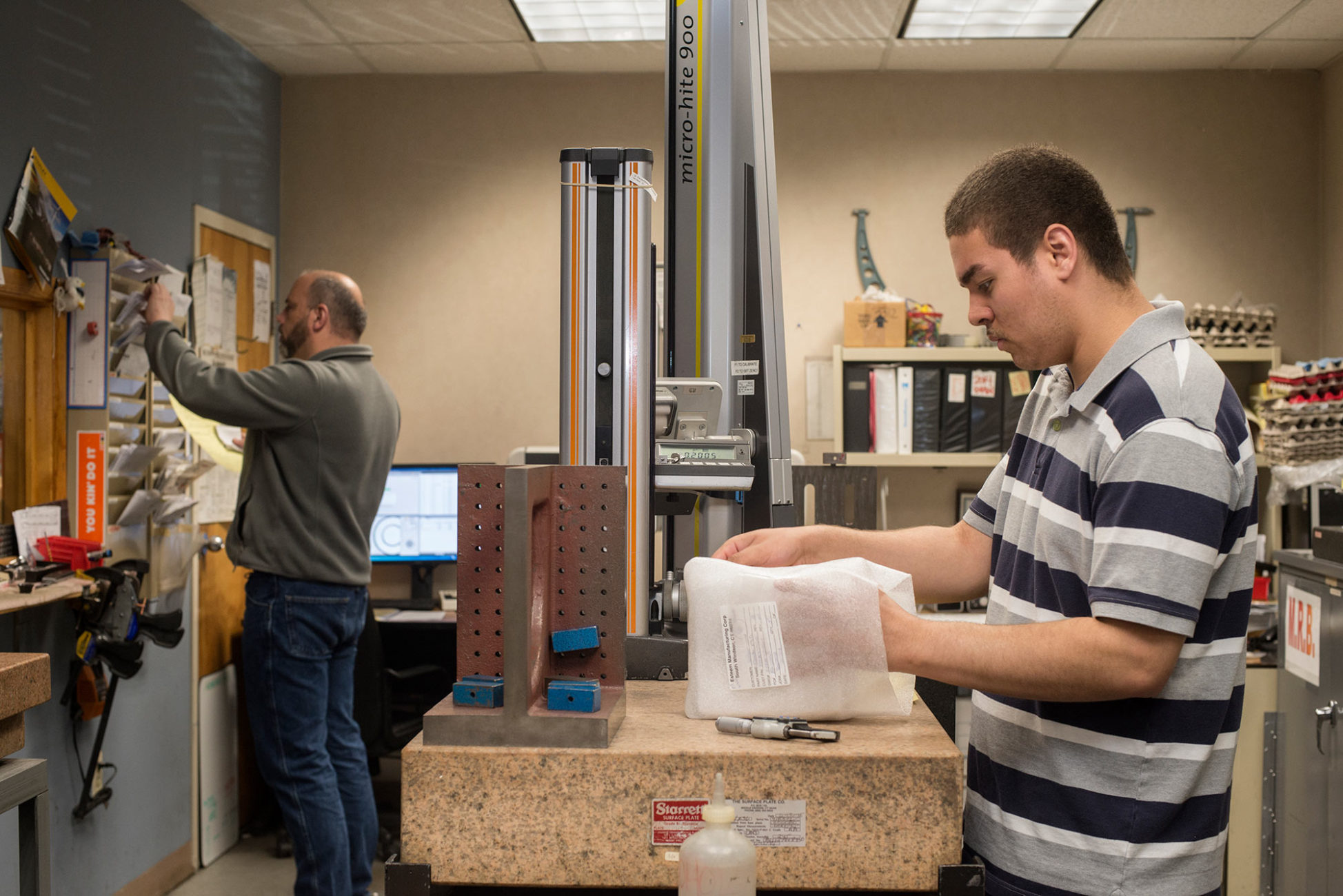

Brown & Sharpe Micro-Hite 900 42”

Brown & Sharpe Micro-Hite 350 14”

Video Optical Inspection:

- Microscope Flexbar Opti-Flex video optical inspection unit & 2d Workshop Software

Two Meyer Gage Pins (inches):

- .011 – .750 (-.0002)

- .060 – .750 (+.0002)

Genx Optical Comparator:

- Digital Readout

- Fiber Optic Edge Detector

Mitutoyo 24 Digital Height Gage

Mitutoyo Digital Dial Bore Gages:

- .5 – 4.4

Starrett Dial Bore Gages:

- .217 – .584

Two Fowler, Hoke & Mitutoyo Grade A Certified Size Blocks

Brown & Sharpe Gage 2000 Manual CMM

Universal Concentricity Gage JLP-10

Two Lab Grade Surface Plates

Multiple Calibrated Thread Gages both Ring and Plug